Ukukhetha inkqubo efanelekileyo yokwenziwa kweendawo zentsimbi yesiko kubalulekile. Kufuneka uqwalasele izinto ezifana nokuchaneka, umthamo kunye neendleko. Umatshini we-CNC unikezela ngokuchaneka okungahambelaniyo kunye nokuguquguquka, oko kuyenza ilungele ukubaleka okuncinci kweendawo ezinzima. Ngakolunye uhlangothi, ukugaywa kwesinyithi kugqwesa kwimveliso ephezulu ngenxa yeendleko-zokusebenza kunye nesantya. Indlela nganye inamandla kunye nemida yayo. Iimfuno zakho ezikhethekileyo ziya kugqiba ukuba yeyiphi inkqubo ekufanele kakhulu. Ukuqonda lo mahluko kukunceda wenze izigqibo ezizizo, uqinisekise ukuba amalungu akho ayahlangabezana neenkcukacha ezifunekayo kunye nomgangatho.

CNC Machining for Custom Metal Parts

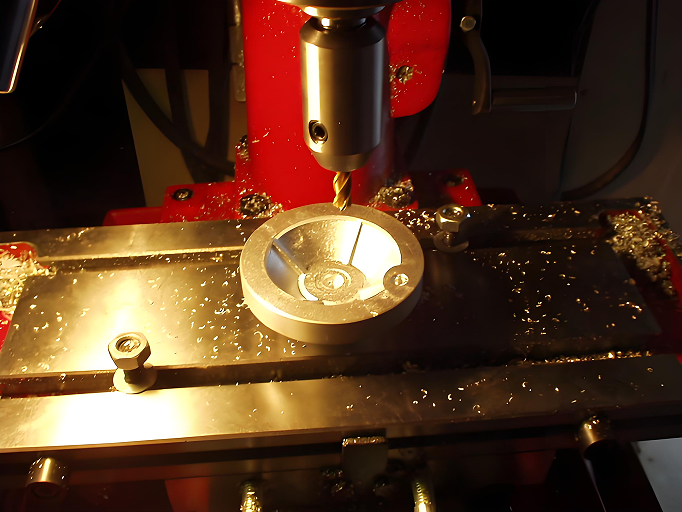

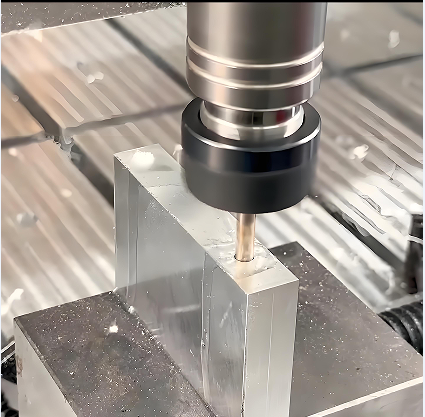

CNC Machining Operations

Umatshini we-CNC ume njengenkqubo yokwenza izinto ezininzi ekuvumela ukuba wenze iinxalenye zentsimbi yesiko ngokuchaneka okumangalisayo. Le nkqubo ibandakanya ukusetyenziswa koomatshini abalawulwa yikhompyutha ukubumba isinyithi sibe ziintlobo ezinqwenelekayo. Ungafezekisa uyilo oluntsonkothileyo kunye neejometri ezintsonkothileyo ezinokuba ngumngeni ngezinye iindlela. Oomatshini be-CNC basebenza ngokulandela imiyalelo ecwangcisiweyo, beqinisekisa ukuba inxalenye nganye ihlangabezana nemigaqo echanekileyo. Oku kuchanekileyo kwenza ukuba umatshini we-CNC ulungele ukuvelisa iindawo ezichanekileyo kunye nokunyamezela okuqinileyo, ngakumbi xa ujongene nezinto ezincinci okanye ze-niche.

Izibonelelo zeCNC Machining

Xa ukhetha ukwenziwa komatshini we-CNC kumacandelo akho entsimbi yesiko, ufumana iingenelo ezininzi:

- Ukuchaneka okuphezulu: Umatshini we-CNC uyagqwesa ekuhambiseni iinxalenye ngokuchaneka okukhethekileyo. Oku kubalulekile xa ufuna amalungu angena ngokugqibeleleyo kwiindibano ezinkulu.

- Uyilo oluntsonkothileyo: Ukukwazi ukuvelisa uyilo oluntsonkothileyo noluntsokothileyo luseta umatshini we-CNC ngokwahlukileyo. Unokwenza iinxalenye ezineempawu ezineenkcukacha ezinokuthi ezinye iinkqubo zibe nzima ukuziphindaphinda.

- Ukuqina: Iindawo eziveliswe ngomatshini we-CNC ziyaziwa ngokomelela kwazo. Oku komelela kuqinisekisa ukuba iikhomponenti zakho zimelana nezicelo eziyimfuneko.

- Ukuguquguquka kwezinto: Umatshini we-CNC usebenza ngoluhlu olubanzi lwezixhobo, okukuvumela ukuba ukhethe olona khetho lufanelekileyo kwiimfuno zakho ezithile.

- Ukusebenza kakuhle: Ukuqhuba imveliso ephakathi ukuya phezulu, i-CNC machining ibonelela ngobuchule obugqwesileyo, iyenza ibe lukhetho olungabizi kakhulu kumacandelo achanekileyo.

Unyino lwe CNC Machining

Ngaphandle kweenzuzo ezininzi, ukwenziwa kwe-CNC kunemida ethile:

- Iindleko zeVolume ephantsi: Ukuqhuba imveliso encinci, iindleko zokuqala zokuseta zingaba phezulu. Oku kusenokungabi lolona khetho lunoqoqosho ukuba ufuna kuphela iinxalenye ezimbalwa.

- Inkunkuma yezinto eziphathekayo: Umatshini we-CNC uquka ukusika izinto eziphathekayo, ezinokukhokelela kwinkunkuma. Oku kunokungafanelanga ukuba usebenza ngezinto ezibizayo.

- Ukuntsonkotha kuSeto: Ukumisela oomatshini be-CNC kufuna abaqhubi abanezakhono kunye neprogram echanekileyo. Oku kuntsonkotha kunokonyusa amaxesha okukhokelela kwiiprojekthi ezintsha.

Ngokuqonda le miba ye-CNC machining, unokumisela ngcono ukuba yinkqubo efanelekileyo yeendawo zakho zentsimbi yesiko. Nokuba ubeka phambili ukuchaneka, ukuntsonkotha, okanye ukuqina, iCNC machining ibonelela ngesisombululo esithembekileyo kwiimfuno ezininzi zokwenziwa.

Ukuphoswa kweMetal kuMalungu eSiko seMetal

Inkqubo yokuphosa isinyithi

Ukuphoswa kwesinyithi yinkqubo yokuvelisa ebandakanya ukudala isikhunta ukubumba iindawo zakho zetsimbi zesiko. Ugalela isinyithi esinyibilikisiweyo kolu bumba, ukuze luphole kwaye luqine ngokupheleleyo. Le ndlela inokuvelisa iindawo ezintsonkothileyo nezintsonkothileyo ezinobukhulu obahlukeneyo. Ubuchule obahlukeneyo, obufana nokuphosa ukufa, bulungiselelwe ukuhlangabezana noyilo oluthile kunye neemfuno zemveliso. I-Die casting, umzekelo, isebenzisa uxinzelelo oluphezulu ukufaka isinyithi esinyibilikisiweyo kwisingundo sentsimbi, esinokuphinda sisetyenziswe ngamaxesha amaninzi. Le nkqubo isebenzayo ngokukodwa ekudaleni iindawo ezinzima zejometri.

IiNzuzo zeMetal Casting

Xa ukhetha ukwenza isinyithi, ufumana iingenelo ezininzi:

- Uyilo lokuguquguquka: Ukwenziwa kwesinyithi kukuvumela ukuba wenze iimilo ezintsonkothileyo kunye neejometri ezintsonkothileyo ezinokuba ngumngeni kwezinye iindlela.

- Iindleko-Ukusebenza: Ukuveliswa komthamo ophezulu, ukuchithwa kwesinyithi kubonisa ukuba yindleko ngenxa yokukwazi ukuphinda kusetyenziswe iimbumba kunye nokuvelisa iinxalenye ngokukhawuleza.

- Ukuguquguquka kwezinto: Ungasebenzisa uluhlu olubanzi lwesinyithi ekugaleleni, kukunika ukuguquguquka kokukhetha eyona nto ilungileyo kwisicelo sakho.

- Ubuchule boMveliso: Intsimbi yokuphosa iyagqwesa ekuveliseni ubuninzi bezahlulo ngokufanelekileyo, iyenza ilungele amashishini afuna imveliso ngobuninzi.

Unyino lweMetal Casting

Ngaphandle kweenzuzo zayo, ukuphoswa kwesinyithi kunemida ethile:

- Iindleko zokuSeta okuQala: Ukudala i-molds kunokuba yindleko, ngakumbi kwizakhiwo ezinzima. Oku kusenokungabi nako ukonga kwimveliso yomthamo ophantsi.

- Umphezulu Gqiba: Amalungu avelisiweyo ngokuphosa anokufuna iinkqubo ezongezelelweyo zokugqiba ukufezekisa umgangatho ofunekayo.

- Ukuchaneka koMda: Ngelixa ukuphosa kunokuvelisa iimilo ezintsonkothileyo, ukufezekisa ukunyamezelana okuqinileyo kunokuba ngumngeni xa kuthelekiswa nomatshini weCNC.

Ngokuqonda le miba yokuphoswa kwentsimbi, unokuvavanya ngcono ukuba yinkqubo efanelekileyo yeendawo zakho zentsimbi yesiko. Nokuba ubeka phambili ukuguquguquka koyilo, ukuphumelela kweendleko, okanye ukusebenza kakuhle kwemveliso, ukuphosa kwesinyithi kunika isisombululo esisebenzayo kwiimfuno ezininzi zokuvelisa.

Ukuthelekiswa ngokuthe ngqo kweCNC Machining kunye neMetal Casting

Ukuntsonkotha kunye noYilo oluGuquguqukayo

Xa kuziwa ekudaleni iinxalenye zentsimbi yesiko, zombini iCNC machining kunye nentsimbi yokuphosa ibonelela ngeenzuzo ezizodwa malunga nobunzima kunye nokuguquguquka koyilo.CNC machiningiyagqwesa ekuveliseni iindawo ezineenkcukacha ezintsonkothileyo kunye nokunyamezelana okuqinileyo. Ungafezekisa uyilo oluchanekileyo kunye noluphindaphindwayo, ulwenza lulungele amacandelo afuna ukucaciswa okuchanekileyo. Le nkqubo ivumela ukuguqulwa okulula, kukuvumela ukuba uvavanye kwaye ucokise iiprototypes ngaphandle kwesidingo sokudala iimolds ezintsha.

Kwelinye icala,ukuphosa isinyithiikhanya ngokukwazi ukuvelisa iimilo eziyinkimbinkimbi kunye neendonga ezincinci kunye neenkcukacha eziyinkimbinkimbi. Ivumela ukuyilwa kweendawo ezingenanto kunye nemingxuma yangaphakathi enokuba ngumngeni ukufezekiswa ngoomatshini. Ngelixa ukujula kungahambelani nokuchaneka komatshini we-CNC, ibonelela ngokuguquguquka okubalulekileyo koyilo, ngakumbi kwimveliso enkulu.

Iindleko kunye nomthamo weMveliso

Uqwalaselo lweendleko ludlala indima ebalulekileyo ekukhetheni phakathi komatshini we-CNC kunye nokuphosa isinyithi kumalungu akho entsimbi yesiko.CNC machiningithande ukuba nexabiso eliphezulu kwimveliso yomthamo ophantsi ngenxa yeendleko zokuqala zokuseta kunye nenkcitho yezinto eziphathekayo. Nangona kunjalo, iba yindleko esebenzayo kwimveliso ephakathi ukuya phezulu, apho ukuchaneka kunye nobunzima kubaluleke kakhulu.

Okuchasene,ukuphosa isinyithiibonakalisa ukonga ngakumbi kwimveliso yomthamo ophezulu. Ukukwazi ukuphinda kusetyenziswe ukubumba kunciphisa iindleko kakhulu, okwenza kube yinto ekhethiweyo yokuveliswa kwemveliso. Ngelixa ukwakhiwa kokungunda kokuqala kunokuba yindleko, ixabiso leyunithi nganye liyehla njengoko umthamo wemveliso unyuka. Oku kwenza ukuphosa kube yinto esebenzayo kumashishini afuna inani elikhulu lamalungu ngokukhawuleza.

Ukuhambelana kwezinto

Ukuhambelana kwezinto ngomnye umba obalulekileyo xa usenza isigqibo phakathi komatshini weCNC kunye nokuphosa isinyithi.CNC machininginikeza uluhlu olubanzi lwezinto onokukhetha kuzo, okukuvumela ukuba ukhethe eyona imathiriyeli efanelekileyo kwiimfuno zakho ezithile. Nokuba ufuna iintsimbi ezifana ne-aluminiyam, intsimbi, okanye i-titanium, i-CNC machining inokwanelisa iimfuno zakho.

Ukuphoswa kwesinyithi, ngelixa uguquguqukayo, unokukhethwa kwezinto eziphathekayo ezilinganiselweyo xa kuthelekiswa nomatshini we-CNC. Isebenza kakuhle ngeentsimbi ezifana ne-aluminiyam, i-zinc, ne-magnesium, kodwa isenokungalungeli zonke izinto. Ngaphandle kwesi sithintelo, ukuphosa kuhlala kulukhetho oluthembekileyo lokuvelisa iindawo ezomeleleyo kunye neziqinileyo.

Ngokuqonda le yantlukwano, unokwenza izigqibo ezinolwazi malunga nokuba yeyiphi inkqubo efanelekileyo kakhulu kwinxalenye yakho yentsimbi yesiko. Nokuba ubeka phambili ukuchaneka, ukusebenza kakuhle kweendleko, okanye ukuhambelana kwezinto, zombini ii-CNC machining kunye nokuphosa ngentsimbi kunika izisombululo ezixabisekileyo kwiimfuno ezahlukeneyo zokwenziwa.

Ukukhetha iNkqubo eLungileyo kwizicelo ezithe ngqo

Ukukhetha phakathi komatshini we-CNC kunye nokuphosa isinyithi kwiindawo zakho zentsimbi yesiko kufuna ukuqwalaselwa ngononophelo kwizinto ezininzi. Indlela nganye ibonelela ngeenzuzo ezizodwa kunye nemida, okwenza ukuba kube yimfuneko ukulungelelanisa ukhetho lwakho kunye neemfuno zakho zesicelo.

Izinto Emaziqwalaselwe

-

Umthamo weMveliso: Ukuba ufuna inani elikhulu lamalungu, ukuphoswa kwesinyithi kuhlala kubonisa ukuba kuneendleko eziphezulu. Ukukwazi ukusebenzisa kwakhona ukubunjwa kunciphisa iindleko kakhulu kwimveliso ephezulu. Nangona kunjalo, kwiibhetshi ezincinci, umatshini weCNC unokuba noqoqosho ngakumbi ngaphandle kweendleko eziphezulu zokuseta.

-

Ukuchaneka nokuNyamezelwa: Umatshini we-CNC ugqwesa ekuhambiseni iindawo ezinokunyamezelana okuqinileyo kunye nokuchaneka okuphezulu. Oku kuyenza ilungele usetyenziso apho iinkcukacha ezithe ngqo zibalulekile. Ukwenziwa kwesinyithi, ngelixa kukwazi ukuvelisa iimilo ezintsonkothileyo, akunakufikelela kwinqanaba elifanayo lokuchaneka njengomatshini we-CNC.

-

IiMfuneko zezinto eziphathekayo: Cinga ngezinto oceba ukuzisebenzisa. I-CNC machining ibonelela ngoluhlu olubanzi lwezinto onokukhetha kuzo, ezihlala iintsimbi ezinjenge-aluminiyam, intsimbi, kunye ne-titanium. Ukuphoswa kwesinyithi kusebenza kakuhle ngeentsimbi ezifana ne-aluminiyam, i-zinc, kunye ne-magnesium kodwa inokungahambelani nazo zonke izixhobo.

-

Ukuntsonkotha koYilo: Kuyilo oluntsonkothileyo oluneempawu ezineenkcukacha, iCNC machining ibonelela ngokuguquguquka okungahambelaniyo. Ungaluguqula ngokulula uyilo ngaphandle kokudala iimbumba ezintsha. Ukwenziwa kwesinyithi, nangona kunjalo, kuvumela ukuyilwa kweemilo ezintsonkothileyo ezinemingxuma yangaphakathi, enokuba ngumceli mngeni ukufezekiswa ngoomatshini.

-

Ukuqwalaselwa kweendleko: Vavanya iindleko zizonke. Ngelixa umatshini we-CNC unokuba neendleko eziphezulu zangaphambili, iba yindleko esebenzayo kwimveliso ephakathi ukuya phezulu. Ukuphoswa kwesinyithi kunika iindleko eziphantsi zeyunithi nganye kwimveliso yobuninzi, okwenza ukuba ifaneleke kumashishini afuna ubuninzi beengxenye ngokukhawuleza.

Iingcebiso ezingqale kuShishino

-

Ushishino lweemoto: Kwizixhobo zemoto ezifuna ukuchaneka okuphezulu kunye namandla, ukucwangciswa kwe-CNC kuhlala kuthandwa. Iqinisekisa ukuba iindawo ziyahlangabezana nemigangatho engqongqo yomgangatho kwaye zingenamthungo kwiindibano ezinkulu.

-

Ishishini le-Aerospace: Usetyenziso lwe-aerospace lufuna iinxalenye ngokuchaneka okungaqhelekanga kunye nokuqina. Umatshini we-CNC ubonelela ngokuchaneka okufunekayo kumacandelo abalulekileyo, ukuqinisekisa ukhuseleko kunye nokusebenza.

-

I-Electronics yabathengi: Kwi-electronics yabathengi, apho ububunzima boyilo kunye nezakhiwo ezikhaphukhaphu ziyimfuneko, ukuphosa ngetsimbi kunokuba luncedo. Ivumela ukuveliswa kweemilo ezintsonkothileyo ngokufanelekileyo.

-

Izixhobo zoShishino: Kwizixhobo zoshishino ezifuna iindawo eziqinileyo kunye nezizinzileyo, ukuchithwa kwetsimbi kunika isisombululo esineendleko zokuvelisa ubuninzi. Inika amandla ayimfuneko kunye nokuhambelana kwezicelo ezifunayo.

Ngokuqonda le miba kunye neengcebiso ezithe ngqo kwishishini, unokwenza izigqibo ezinolwazi malunga neyona nkqubo ifanelekileyo yokuvelisa kwiindawo zakho zetsimbi. Nokuba ubeka phambili ukuchaneka, ukusebenza kakuhle kweendleko, okanye ukuhambelana kwezinto, ukulungelelanisa ukhetho lwakho kunye neemfuno zesicelo sakho kuqinisekisa iziphumo ezilungileyo.

Ukukhetha phakathi komatshini we-CNC kunye nokuphosa isinyithi kufuna ukuqonda iiyantlukwano zabo eziphambili. Umatshini we-CNC unikezela ngokuchaneka okuphezulu kunye nokuguquguquka, okwenza kube ngokufanelekileyo kuyilo oluntsonkothileyo kunye nokuqhutywa kwemveliso encinci. I-Metal casting, nangona kunjalo, igqwesa kwimveliso ephezulu kunye neendleko ezifanelekileyo kunye nesantya. Ukukhetha inkqubo elungileyo, qwalasela imiba efana nomthamo wemveliso, iimfuno ezichanekileyo, kunye nokuhambelana kwezinto. Ukubonisana neengcali kunokubonelela ngeengcebiso ezilungiselelweyo, ukuqinisekisa ukuba inkqubo yakho yokuvelisa ihambelana neemfuno zakho zeprojekthi. Ngokulungelelanisa iimfuno zakho zemveliso kunye nendlela efanelekileyo, uqinisekisa iziphumo ezifanelekileyo kwiindawo zakho zentsimbi yesiko.