Iiprofayili ze-aluminium extrusion zitshintsha umdlalo kwimveliso yeemoto. Uyaxhamla kububhetyebhetye boyilo oluphuculweyo, okuvumela ukwenziwa kwezinto ezintsha zezithuthi. Iimpawu ezikhaphukhaphu zezi profayili zinceda ukunciphisa ubunzima besithuthi bubonke, okuphucula ukusebenza kakuhle kwamafutha kunye nokunciphisa ukukhutshwa. Imarike ye-aluminiyam ye-automotive extrusion yayixabiswaI-USD 76.58 yeebhiliyoni ngo-2023kwaye kuqikelelwa ukuba ifikelele kwi-USD 147.08 yebhiliyoni ngo-2031. Oku kukhula kubonisa utshintsho oluqinileyo kwiindlela ezizinzileyo kunye nokunyuka kweemfuno zezithuthi zombane, ezixhomekeke kwizinto ezilula ukuze zisebenze ngokufanelekileyo.

Izinto eziphambili zokuThatha

- Iiprofayili ze-Aluminium extrusion zinciphisa ubunzima besithuthi, ukuphucula ukusebenza kakuhle kwamafutha kunye nokunciphisa ukukhutshwa. Oku kunokukhokelela ekuthotyweni kobunzima obungama-35 eekhilogram ngesithuthi ngasinye.

- Ezi profayili zomeleza ukhuseleko lwesithuthi ngokufunxa amandla empembelelo ngexesha longquzulwano. Uyilo lwabo luvumela ukuguqulwa okungcono, okuphucula ukuphahlazeka.

- Iiprofayili ze-Aluminiyam extrusion ziiindleko-esebenzayo ekuhambeni kwexesha. Nangona iindleko zokuqala zezixhobo zinokuba phezulu, zihlala zikhokelela kwiindleko zokugcinwa okuphantsi kunye nokuqina okungcono.

- Ukusebenzisa i-aluminiyamixhasa uzinzokushishino lweemoto. Ingaqulatha ukuya kuthi ga kwi-75% yomxholo osetyenzisiweyo kwaye i-aluminiyam yokurisayikilisha isebenzisa ama-95% amandla angaphantsi kunokuvelisa i-aluminiyam entsha.

- Iiprofayili ze-Aluminiyam zinezinto ezininzi kuyilo lweemoto, zilungele amacandelo esakhiwo, iimpawu zobuhle, kunye neenkqubo zolawulo lwe-thermal, ukuphucula zombini ukusebenza kunye nesimbo.

Izinto eziluncedo zeAluminiyam Extrusion Profiles

Iipropati eziKhala

Iiprofayili ze-aluminium extrusion zinciphisa kakhulu ubunzima besithuthi, obuchaphazela ngokuthe ngqo ukusebenza kunye nokusebenza kakuhle. Ngokusebenzisa ezi profayili, ungafikelela kwi-avareji ukunciphisa ubunzima malungaIiponti ezingama-35 ngesithuthi ngasinye. Oku kuncitshiswa kuqikelelwa ukuba kunyuke ukuya phantseIiponti ezingama-45 ngesithuthi ngasinyengo-2025. Ukugcinwa kobunzima obunjalo bukhokelela ekuphuculeni ukusebenza kakuhle kwamafutha kunye nokukhutshwa okuphantsi, okwenza izithuthi zakho zibe zihambelana nokusingqongileyo. Enyanisweni, imibutho ye-aluminiyam eluncedo inokubangela ukuba35% ukunciphisa ubunzima bomzimbaxa kuthelekiswa nabalingane bentsimbi yemveli. Olu ncedo lukhaphukhaphu lubalulekile njengoko ishishini leemoto litshintshela kwiindlela ezizinzileyo.

Ukomelezwa kunye noKuhlala ixesha elide

Ungothuka kukufunda ukuba iiprofayili ze-aluminium extrusion aziboneleli kuphela ngezibonelelo ezikhaphukhaphu kodwa zikwabonelela ukomelela kunye nokuqina. Iimpawu zomatshini ze-aluminium zinegalelo kwimigangatho yokhuseleko lwesithuthi. Umzekelo, amandla okuqina eprofayili ye-aluminium extrusion aqala ukusuka180-220 MPa, ngelixa amandla esivuno anokufikelela90-140 MPa. Xa kuthelekiswa, intsimbi yemveli idla ngokuba namandla okuqina455 MPakunye namandla emveliso ye380 MPa. Nangona kunjalo, ukukwazi kwe-aluminiyam ukufunxa amandla ngexesha leempembelelo kwenza kube lukhetho olukhuselekileyo kuyilo lwesithuthi. Ipesenteji yobude be-aluminiyam, eqala ukusuka10-25%, ivumela ukuguqulwa okungcono ngaphandle kokungaphumeleli, ukuphucula ukhuseleko lwesithuthi ngokubanzi.

Iindleko-Ukusebenza

Xa ucingaiindleko zokuvelisa, iiprofayili ze-aluminium extrusion zibonisa ukhetho lokukhuphisana. Ngelixa iindleko zokuqala zezixhobo ze-aluminiyam zinokuba phezulu ngenxa yophuhliso lokufa kunye neengubo ezikhethekileyo, iinzuzo zexesha elide zihlala zidlula ezi ndleko. Umzekelo, iindleko zokugcina ezinxulumene nezithuthi ezisebenzisa iiprofayili ze-aluminiyam zithande ukuba phantsi ngokuhamba kwexesha. Uhlalutyo oluqhelekileyo lweendleko zomjikelo wobomi lubonisa ukuba izithuthi ze-aluminium zifuna ukulungiswa rhoqo kunye nokugcinwa rhoqo xa kuthelekiswa neentsimbi zentsimbi.

| Uhlobo lwezinto eziphathekayo | Iindleko zeFactors | Ukuthelekisa kwiAluminiyam |

|---|---|---|

| Aluminiyam | Iindleko eziphezulu zezixhobo, uphuhliso lokufa, iingubo ezikhethekileyo | Ngokuqhelekileyo iphezulu kunentsimbi ngenxa yezixhobo kunye namaxabiso ezinto eziphathekayo |

| Intsimbi | Iindleko ezisezantsi zezixhobo, amaxabiso estampu ngokukhawuleza | Ixabiso elingaphezulu kune-aluminiyam kwizicelo ezininzi |

| Umdibaniso | Iyahluka ngokusekelwe kwisicelo | Ukusebenza kweendleko kunokukhuphisana ngokuxhomekeke kwinkqubo |

IiNzuzo zokuZinza

Iiprofayili ze-Aluminiyam extrusion zidlala indima ebalulekileyo ekwandiseni uzinzo kushishino lweemoto. Iipropathi zabo ezikhaphukhaphu aziphuculi nje ukusebenza kakuhle kwamafutha kodwa zikwanciphisa kakhulu ukukhutshwa kwezinto ngexesha lokusebenza kwesithuthi. Ngokukhetha i-aluminium, unokunceda izithuthi zakho ukuba zihlangabezane neethagethi kunye nemimiselo engqongqo yeNdalo, iNtlalo, kunye noLawulo (ESG). Nazi ezinye iingenelo ezingundoqo zozinzo lokusebenzisa iiprofayili ze-aluminium extrusion:

- Ukusetyenziswa kwamandla: Ukuveliswa kwe-aluminiyam kunamandla amakhulu, anokuchaphazela ukukhutshwa. Nangona kunjalo, ubume obukhaphukhaphu be-aluminiyam bunceda ekuphuculeni ukusebenza kakuhle kwamafutha, okukhokelela kukhupho oluphantsi lokusebenza.

- IiNzuzo zokuRecycling: Olona ncedo lubalulekileyo lwe-aluminiyam kukuphinda isetyenziswe. Ukusetyenziswa kwakhona kwealuminiyamAmandla angaphantsi ngama-95%.kunokuvelisa i-aluminiyam entsha ngemathiriyeli ekrwada. Le nkqubo ikhokelela ekuncipheni okukhulu kwezinto ezikhutshwayo.

- Ukukhethwa kwezinto: Ukukhethwa kwe-aluminium kuchaphazela ubunzima besithuthi, ukusetyenziswa kwamandla, kunye nefuthe elilinganayo le-carbon dioxide (CO2e). Ngokukhetha iiprofayili ze-aluminium extrusion, ufaka isandla kwinkqubo yokuvelisa ezinzileyo.

- UKhuseleko lweSibonelelo sexesha elide: Ukusebenzisa i-aluminiyam kwandisa ukuqikelelwa kweendleko kunye nokuzinza. Olu zinzo lubalulekile njengoko ishishini leemoto lijongene neendleko zempahla eziguquguqukayo kunye nemingeni yokubonelela.

Le theyibhile ilandelayo ishwankathela indlela iiprofayili ze-aluminiyam e-extrusion ezichaphazela ngayo unyawo lwekhabhoni yokwenziwa kweemoto:

| Umba | Impembelelo kwiCarbon Footprint |

|---|---|

| Ukusetyenziswa kwamandla | Imveliso yeAluminiyam inamandla kakhulu, ichaphazela ukukhutshwa. |

| Iipropati eziKhala | Ukuphucula ukusebenza kakuhle kwamafutha, ukunciphisa ukukhutshwa kokusebenza. |

| IiNzuzo zokuRecycling | Ukurisayikilisha i-aluminiyam isebenzisa ama-95% amandla angaphantsi kunemveliso yokuqala, ekhokelela kukukhutshwa okuphantsi. |

| Ukukhethwa kwezinto | Ichaphazela ubunzima bezithuthi, ukusetyenziswa kwamandla, kunye nefuthe le-CO2e. |

| UKhuseleko lweSibonelelo sexesha elide | Ukwandisa ukuqikelelwa kweendleko kunye nozinzo. |

Ukongeza, ukuya kuthi ga75%ye-aluminium esetyenziswe kwiiprofayili ze-extrusion kwizicelo zeemoto zinokuvela kumxholo ohlaziyiweyo wasemva komthengi. Eli zinga liphezulu lokurisayikilisha aligcini nje kuphela ubutyebi kodwa likwanciphisa impembelelo yokusingqongileyo eyayanyaniswa nokutsalwa kwemathiriyeli ekrwada.

Ngokudibanisa iiprofayili ze-aluminium extrusion kuyilo lwemoto yakho, unegalelo elibonakalayo kwikamva elizinzileyo. Ukudityaniswa kweempawu ezikhaphukhaphu, ukusebenza kakuhle kwamandla, kunye nesakhono sokuphinda sisetyenziswe kubeka ialuminiyam njengeyona nto iphambili kukhangelo lwezisombululo zeemoto eziluhlaza.

Ukusetyenziswa kweeProfayili zeAluminium Extrusion kwi-Automotive Design

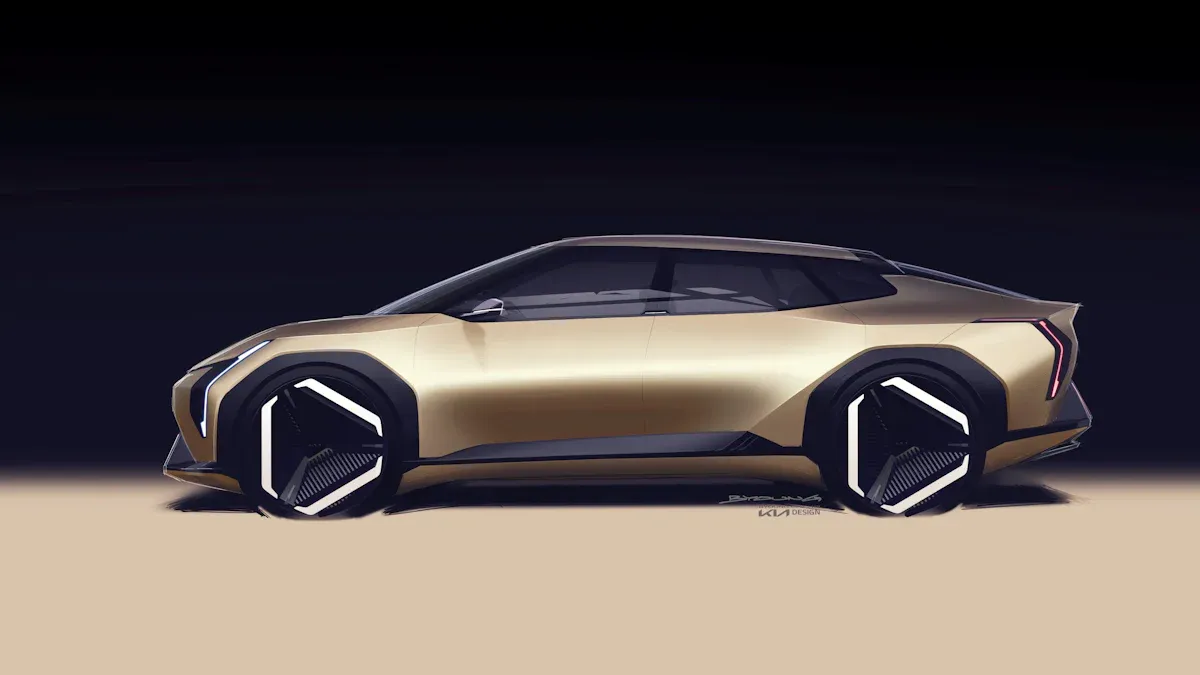

Iiprofayili ze-aluminium extrusiondlala indima ebalulekileyo kuyilo lweemoto lwale mihla, uphucula ukusebenza kunye nobuhle. Ukuguquguquka kwazo kukuvumela ukuba uziphumeze kwizicelo ezahlukeneyo, ukusuka kulwakhiwo ukuya kwizinto ezintsonkothileyo zobuhle.

Amacandelo oLwakhiwo

Unokufumana iiprofayili ze-aluminium extrusion kumacandelo amaninzi abalulekileyo ezithuthi. Ezi profayili zinika amandla ayimfuneko ngelixa zinciphisa kakhulu ubunzima. Usetyenziso oluqhelekileyo lubandakanya:

- Chassis Components: Ezi profayili zibonelela ngobulungisa bolwakhiwo, ziqinisekisa ukuba isithuthi sihlala somelele kodwa sikhaphukhaphu.

- Izakhiwo zokuphahlazeka: Zifunxa amandla empembelelo, ziphucula ukhuseleko lwabakhweli ngexesha longquzulwano.

- IiNdawo zeBattery: Kwizithuthi zombane, ezi profayili zikhusela amacandelo abuthathaka, ziqinisekisa ixesha elide kunye nokuthembeka.

- Izakhelo zoMzimba: Kubalulekile ukugcina ubume besithuthi siphela.

- Amacandelo eChassis: Amacandelo aphambili axhasa ubunzima kunye nokuzinza kwesithuthi.

- IiNkqubo zoLawulo lokuNwaba: Kubalulekile kukhuseleko, ezi nkqubo zisebenzisa iiprofayili ze-aluminium ukunciphisa ukwenzakala ngexesha leengozi.

Iiprofayili ze-Aluminium extrusion ziphucula ukonakala kumacandelo ezakhiwo zeemoto. Umzekelo, ukusebenzisa ezi profayili kunokukhokelela ekubeni aUkunciphisa nge-4.74%.kumthwalo ophakamileyo ngexesha leempembelelo. Ukongeza, banokunyusa ukufunxwa kwamandla7%, ukuphucula ukhuseleko lwesithuthi ngokubanzi.

| Ukufumana | Inkcazo |

|---|---|

| Incopho yokuNcitshiswa komthwalo | Ukuya kuthi ga kwi-4.74% yokunciphisa umthwalo ophezulu (Pmax) kunye nokuyeka. |

| Ukonyuka kwaMandla | I-7% yokwanda kwe-absorption yamandla (i-Ea) ibonwe kunye nokuyeka. |

| Crush Force Efficiency | I-12.69% yokwanda kwe-crush force efficient (CFE) ephawulwe ngokuyeka umatshini. |

Iimpawu zobuhle

Iiprofayili ze-aluminium extrusion nazo zinegalelo elikhulu kwisibheno sobuhle bezithuthi. Iinzuzo zabo zokuyila zivumela umxube wokusebenza kunye nesitayela. Iinzuzo eziphambili ziquka:

| Inzuzo | Inkcazo |

|---|---|

| Umlinganiselo wamandla kubunzima | I-Aluminiyam ikhaphukhaphu kunentsimbi ngelixa igcina amandla aphezulu olwakhiwo, ilungele ukusetyenziswa kweemoto. |

| Ukuguquguquka koyilo | I-extrusion yesiko ivumela iiprofayili ezintsonkothileyo nezintsonkothileyo, ziphucula zombini ukusebenza kunye nobuhle. |

| Ukumelana nokubola | Ukuxhathisa kwe-aluminiyam yendalo kwi-corrosion iyenza ilungele ukusetyenziswa kweemoto ezivezwe kwiindawo ezahlukeneyo. |

Unokwenza ngokwezifiso izithuthi zangaphandle kunye nezangaphakathi usebenzisa iiprofayili ze-aluminium extrusion. Olu hlengahlengiso lubandakanya izakhiwo zomzimba, izinto ze-chassis, kunye namalungu angaphakathi. Umzekelo, unokwenza iifreyimu zedeshibhodi ezilungiselelweyo kunye nezibiyeli zokuhlala eziphucula zombini ubuhle kunye nokusebenza.

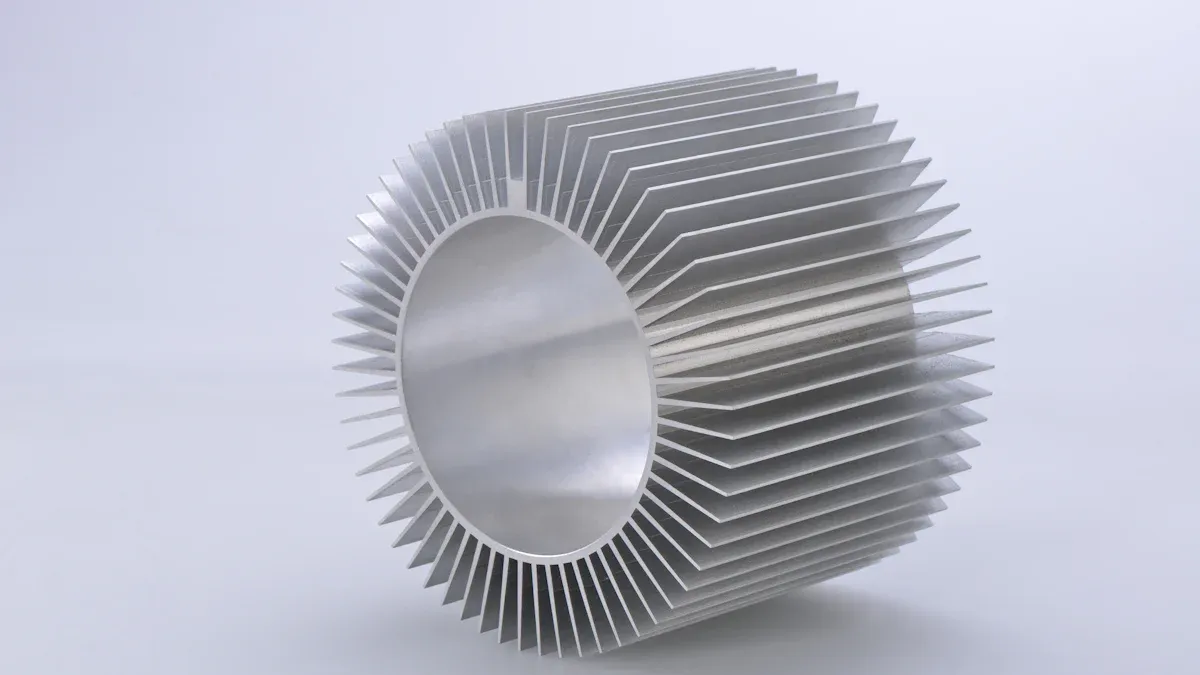

Izitshintshi zobushushu kunye neRadiators

Kwiinkqubo zokupholisa iimoto, iiprofayili ze-aluminium extrusion zigqwesa ngokufanelekileyo. Zenziwe ngendlela ekhethekileyoukusebenza thermal, ukuqinisekisa ukutshintshiselana kobushushu. Iimpawu eziphambili ziquka:

| Uphawu | Inkcazo |

|---|---|

| Ukusebenza kweThermal | Yenzelwe ukusebenza kwe-thermal ekhethekileyo, iqinisekisa ukutshintshiselana kobushushu. |

| Ukuqina | Gxininisa ekomeleleni kokusetyenziswa ixesha elide kwizicelo ezahlukeneyo. |

| Uyilo oluKhala | Ilungele uluhlu olubanzi lokucwangciswa kwe-radiator ngenxa yeempawu ezilula. |

I-aluminium alloys, efana ne-6061 kunye ne-6063, iyaziwa ngokuba ne-thermal conductivity ephezulu. Le propati iyimfuneko kulawulo olusebenzayo lobushushu kwiinkqubo zokupholisa iimoto. Ubume bazo obukhaphukhaphu kunye nokuguquguquka kuyilo ngakumbi komeleza ukufaneleka kwabo kwezi zicelo.

Ngokudibanisa iiprofayili ze-aluminium extrusion kuyilo lwemoto yakho, awuphuculi nje kuphela imfezeko yesakhiwo kunye nobuhle kodwa ukwaphucula ulawulo lobushushu, ukwenza izithuthi zakho zisebenze ngakumbi kwaye zibe nomtsalane.

Izinto ezintsha kwiZithuthi zoMbane eziSebenzisa iiProfayili zeAluminium Extrusion

Ibhetri Housing Solutions

Unokwandisa kakhulu ukhuseleko kunye nokusebenza kakuhle kwezithuthi zombane ngokusebenzisaiiprofayili ze-aluminium extrusionyezindlu zebhetri. Ezi profayili zinika ezininziiinzuzo eziphambili:

- Ukuqina: Baqinisekisa ukuba iipakethi zebhetri zikhuselwe kakuhle kwiimpembelelo.

- Ikhaphukhaphu: Oku kunegalelo ekunciphiseni ubunzima obubalulekileyo, kubalulekile ekusebenzeni kakuhle kwesithuthi sombane.

- Ukuthotyelwa koMgaqo: Iiprofayili ze-Aluminiyam zihlangabezana nemigangatho yokhuseleko lweendawo ezivaliweyo zebhetri.

- INdibano Elula: Baququzelela ukwakhiwa lula kweemodyuli zebhetri.

- Ukukhuselwa koMbane: Oku kukhusela amalungu e-elektroniki ekuphazamisekeni.

- Ukufunxwa kwamandla: I-Aluminiyam iqhuba ngcono kwiimeko zokuwa xa kuthelekiswa nezinye izinto.

Ngokusebenzisa i-aluminium, ufezekisa ukunciphisa ubunzima ukuya kuthi ga50%xa kuthelekiswa neendawo ezivaliweyo zebhetri yentsimbi. Oku kugcinwa kobuninzi kuphucula uluhlu lwesithuthi kunye nokusebenza kakuhle kwamandla.

Uyilo lweChassis olulula

Iiprofayili ze-Aluminiyam extrusion zidlala indima ebalulekileyo ekuyileni i-chassis ekhaphukhaphu kwiimoto zombane. Ngokutshintsha intsimbi nge-aluminium, unokufezekisa ukunciphisa ubunzima25-30%. Oku kuncitshiswa konyusa isantya kunye nokusebenza kakuhle kwamandla. Ubume be-aluminiyam buqinisekisa ukuba ibhetri ihlala ikhuselekile ngexesha leengozi, okomeleza amandla e-chassis ngokubanzi.

| Inzuzo | Inkcazo |

|---|---|

| Ukunyaniseka kwesakhiwo | Ikhusela ibhetri ngexesha lokuntlitheka, okomeleza amandla e-chassis ngokubanzi. |

| Ulawulo lobushushu | Ikhupha ubushushu obuveliswe ngexesha lokutshaja kunye nokusebenza, kubalulekile kukhuseleko lwebhetri. |

| Ukhuseleko olulula | Inciphisa ubunzima bebhetri, iphucula ukusebenza kakuhle kwesithuthi kunye noluhlu. |

| Ukwenza ngokwezifiso | Iitshaneli ezidityanisiweyo zokupholisa kunye neengcingo zinciphisa ukuntsokotha koyilo kunye nokubalwa kwecandelo. |

| Iinkqubo zolawulo lokuntlitheka | Yenzelwe ukonakala ngokuqikelelwayo phantsi kwempembelelo, ukufunxa amandla kunye nokukhusela abakhweli. |

IiNkqubo zoLawulo lweThermal

Ulawulo olusebenzayo lwe-thermal luyimfuneko ekusebenzeni kunye nokuphila ixesha elide kwezithuthi zombane. Iiprofayili ze-aluminium extrusion zigqwesa kule ndawo ngenxa ye-thermal conductivity yendalo. Unokusebenzisa i-aluminiyam yesiko kwizindlu zebhetri kunye neepleyiti zokupholisa ukuphucula ulawulo lobushushu.

- Ukusebenza kakuhle kwe-thermal dissipation: Oku kuphucula ubomi bebhetri kunye nokusebenza.

- Ubulula bendalo: Inegalelo ekusebenzeni kakuhle kwesithuthi, ngakumbi ngexesha leemeko ezifunwa kakhulu.

- Iityhubhu zokupholisa zenyoka: Yenziwe nge-aluminiyam ekhutshiweyo, ezi ziphucula ukuhamba okupholileyo, zigcina amaqondo obushushu afanelekileyo kwiiseli zebhetri.

Ngokudibanisa iiprofayili ze-aluminium extrusion kwiinkqubo zakho zokulawula ukushisa, uqinisekisa ukuba isithuthi sakho sombane sisebenza ngokufanelekileyo nangokuthembeka.

Ukuthelekiswa kweeProfayili zeAluminium Extrusion kunye neMathiriyeli yesiNtu

Intsimbi vs. Aluminiyam

Xa uthelekisa intsimbi kunye ne-aluminium, uya kuqaphela ukungafani okuphawulekayo kwiipropati zemishini kunye nokusetyenziswa. Nazi iingongoma ezibalulekileyo ekufuneka uziqwalasele:

- Tensile strength: Uluhlu lwentsimbi ukusuka400 MPa ukuya 500 MPa, ngelixa i-aluminiyam ijikeleze90 MPa. Oku kubonisa ukuba intsimbi inokumelana noxinzelelo olukhulu.

- Amandla acinezelayo: Intsimbi idlula i-aluminium, ithwala imithwalo ephezulu ngaphandle kokuguqulwa okubalulekileyo.

- Unikeze Amandla: Amandla emveliso yentsimbi malunga250 MPa, xa kuthelekiswa ne-aluminiyam40 MPa, ebonisa ukomelela kwentsimbi.

Ngelixa i-aluminiumkhaphukhaphu, amandla aphezulu entsimbi avumela ukuyila okuncinci, ukwandisa amandla okuthwala umthwalo. Nangona kunjalo, indalo ye-aluminiyam ekhaphukhaphu yenza ukuba ilungele izicelo apho ukunciphisa ubunzima kubalulekile.

Izinto ezihlanganisiweyo

Izinto ezidibeneyo zibonelela ngeenzuzo ezizodwa kwizicelo zeemoto. Badibanisa izinto ezahlukeneyo ukuze bafezekise ukusebenza okuphezulu. Nantsi indlela abathelekisa ngayo kwiiprofayili ze-aluminium extrusion:

- Ubunzima: I-Composites ingaba lula kune-aluminium, kuxhomekeke kwizinto ezithile ezisetyenzisiweyo.

- Amandla: Ezinye izinto ezidityanisiweyo zibonisa umlinganiselo ophezulu wokuqina kobunzima, nto leyo ebenza bakhuphisane ne-aluminiyam kwizicelo ezithile.

- Iindleko: Ngokuqhelekileyo, ii-composites zingabiza ngaphezu kwe-aluminium ngenxa yeenkqubo zokuvelisa eziyinkimbinkimbi.

Iiprofayili ze-aluminium extrusionzihlale zilukhetho oludumileyo ngenxa yokulinganisela kweendleko, ubunzima, kunye namandla, okubenza balungele usetyenziso lwezithuthi ezahlukeneyo.

Iimetriki zokuSebenza

Xa uvavanya iimethrikhi zokusebenza, iiprofayili ze-aluminium extrusion zigqwesa kwiindawo ezininzi:

- Imilinganiselo yovavanyo lokuphahlazeka: Iialloyi zeAluminiyam, ngakumbi ezo zikwindawo5xxx uthotho, ziyaziwa ngamandla abo aphezulu kunye nokuxinana okuphantsi. Olu luhlu luphucula ukusebenza kokuphazamiseka.

- Ukonga Ubunzima: Iiprofayili zeAluminiyam zinokufikelela ukonga ubunzima ukuya kuthi ga25%xa kuthelekiswa nezakhiwo zentsimbi zemveli. Oku kuncipha kunegalelo ekuphuculeni ukusebenza kakuhle kwamafutha kunye nokukhutshwa kwezinto ezikhutshwayo ezisezantsi.

- Ukufunxwa kwamandla: I-Aluminiyam inokufunxa amandla ngokufanelekileyo ngexesha leengozi, iphucula ukhuseleko lwabakhweli.

IiNdlela zexesha elizayo kunye neMingeni yeeProfayili zeAluminiyam Extrusion

Ukuqhubela phambili kwiTekhnoloji ye-Extrusion

Unokulindela inkqubela phambili ebalulekileyoitekhnoloji ye-aluminium extrusionoko kuya kubumba ishishini leemoto. Nalu uphuhliso oluphambili ekufuneka ulubukele:

- Ukunciphisa ukukhutshwa kweCarbon: Abavelisi bajolise ekunciphiseni ukukhutshwa kwekhabhoni kuwo wonke umlambo wexabiso lemveliso ye-aluminium. Olu tshintsho lukhuthaza uzinzo kwaye luhambelane neenjongo zokusingqongileyo zehlabathi.

- Amandla aphezulu Alloys: Uphuhliso lwamandla aphezulu angama-6000 uchungechunge lwe-aluminium alloys luphucula ukuqina kwizicelo zeemoto. Ezi alloys zibonelela ngokusebenza ngcono ngelixa zigcina iimpawu ezilula.

- Ubunakho beMicro-Extrusion: Ukuqaliswa kwe-micro-extrusion kuvumela ukuveliswa kweeprofayili ze-ultra-thin. Esi sikhundla siyimfuneko ekudaleni amacandelo kwizithuthi zombane, apho indawo kunye nokugcinwa kobunzima kubalulekile.

IMbango yeMarike kunye neMiba yesiXeko soBonelelo

I-aluminiyam yeemoto ze-aluminiyam ekhutshiweyo kwimarike ijongene nemingeni ngenxaukuguquguquka kwamaxabiso ezinto eziphathekayo. Unokuqaphela ukuba iindleko zee-ingots ze-aluminium kunye neebhilithi ziphenjelelwa kukuphazamiseka kwekhonkco lokubonelela ngehlabathi, amaxabiso amandla, kunye noxinzelelo lwe-geopolitical. Le miba yenza nzima ukukwazi kwakho ukulawula iindleko zemveliso ngokufanelekileyo. Ukongeza, ukunqongophala kwabasebenzi kunye neebhotile zezothutho zithintela i-aluminium extruders ekuhlangabezaneni neemfuno zokuhanjiswa kwexesha. Ngenxa yoko, unokufumana ukulibaziseka okanye ukonyuka kweendleko zokufumana iiprofayili ze-aluminium kwiiprojekthi zakho zeemoto.

Iingqwalasela zoLawulo kunye nokusiNgqongileyo

Imimiselo yokusingqongileyoidlala indima ebalulekileyo ekwamkelweni kweeprofayili ze-aluminiyam extrusion kushishino lweemoto. Nazi ezinye iimpembelelo eziphambili:

- Imigaqo ikhuthaza ukusetyenziswa kwezinto ezikhaphukhaphu ukuhlangabezana nemigangatho yokukhupha.

- Imigangatho engqongqo yoqoqosho lwamafutha kunye nezigunyaziso zokufakelwa kombane zikhuthaza ukwamkelwa kweeprofayili ze-aluminiyam.

- Imigaqo emalunga nokuphinda isetyenziswe kunye nemithetho-siseko yoqoqosho lwesetyhula iqhuba inguqulelo kwiinkqubo zokurisayikilisha ialuminiyam.

- Utshintsho oluya kwizithuthi zombane (EVs) lukhawuleziswa luxinzelelo olulawulayo, lunyusa imfuno yamacandelo e-aluminium.

Ngokuhlala unolwazi malunga nale mikhwa kunye nemiceli mngeni, ungajonga ngcono imeko eqhubekayo yeeprofayili ze-aluminium extrusion kwicandelo leemoto.

Ukuhlanganiswa kweeprofayili ze-aluminium extrusion ngokuphawulekayo kuguqula imboni yemoto. Uyaxhamla kwiimoto ezikhaphukhaphu ezonyusa ukusebenza kakuhle kwamafutha kunye nokunciphisa ukukhutshwa kwegesi. Ezi profayili zikwaxhasa uyilo oluyilayo, ekuvumela ukuba wenze izithuthi ezihlangabezana nemigangatho yangoku yokuzinza. Njengoko ishishini likhula, ukwamkela iiprofayili ze-aluminiyam extrusion kuya kubaluleka ukuze uhlale ukhuphisana kwaye unoxanduva lokusingqongileyo.

FAQ

Ziziphi iiprofayili ze-aluminium extrusion?

Iiprofayili ze-aluminium extrusionziimilo ezidalwe ngokunyanzela ialuminiyam ngokufa. Le nkqubo ivumela abavelisi ukuba bavelise iimilo ezintsonkothileyo ezikhaphukhaphu, ezinamandla, neziguquguqukayo kwizicelo ezahlukeneyo zeemoto.

Ngaba iiprofayili ze-aluminium extrusion ziluphucula njani ukhuseleko lwesithuthi?

Ezi nkcukacha zifunxa amandla empembelelo ngexesha longquzulwano, okomeleza ukhuseleko lwabakhweli. Uyilo lwabo luvumela ukuguqulwa okungcono ngaphandle kokusilela, okunegalelo ekuphuculeni ukuphahlazeka kwezithuthi.

Ngaba iiprofayili ze-aluminium extrusion zineendleko ezifanelekileyo?

Ewe, ngelixa iindleko zokuqala zezixhobo zinokuba phezulu, iiprofayili ze-aluminiyam zihlala zikhokelela kumaxabiso aphantsi olondolozo ngokuhamba kwexesha. Ukonga kwabo kunye nobume obukhaphukhaphu bunokubangela ukongiwa okukhulu ekusebenzeni kakuhle kwamafutha.

Yiyiphi indima eyenziwa yi-aluminium extrusion profiles kwizithuthi zombane?

Kwizithuthi zombane, iiprofayili ze-aluminium extrusion zibalulekile kwizindlu zebhetri, uyilo lwe-chassis ekhaphukhaphu, kunye neenkqubo zolawulo lobushushu. Baphucula ukhuseleko, ukusebenza kakuhle, kunye nokusebenza kwesithuthi ngokubanzi.

Zizinzile kangakanani iiprofayili ze-aluminium extrusion?

Iiprofayili ze-Aluminiyam extrusion zilugcineke kakhulu. Zingaqulatha ukuya kuthi ga kwi-75% yomxholo osetyenzisiweyo, kwaye i-aluminium yokubuyisela isebenzisa i-95% yamandla angaphantsi kokuvelisa i-aluminium entsha, ukunciphisa kakhulu impembelelo yokusingqongileyo.